Performance Range

Available in 60 cross sections and a capacity range of 33 to 5,141 nominal tons (144 to 22,596 Kw).

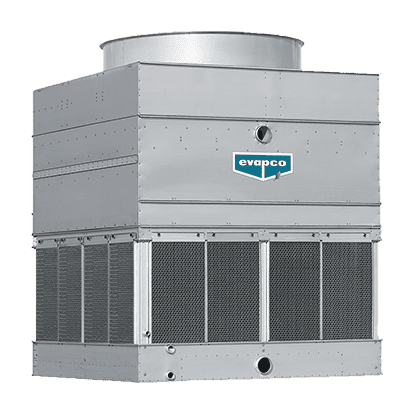

AT The original compact, low-horsepower, induced draft, axial fan solution for all outdoor applications.

UT All of the benefits of the AT design, built with EVAPCO’s Super-Low-Sound Fan for sound-sensitive applications.

USS All-stainless-steel AT construction for maximum corrosion resistance, ideal for coastal and other corrosive environments.